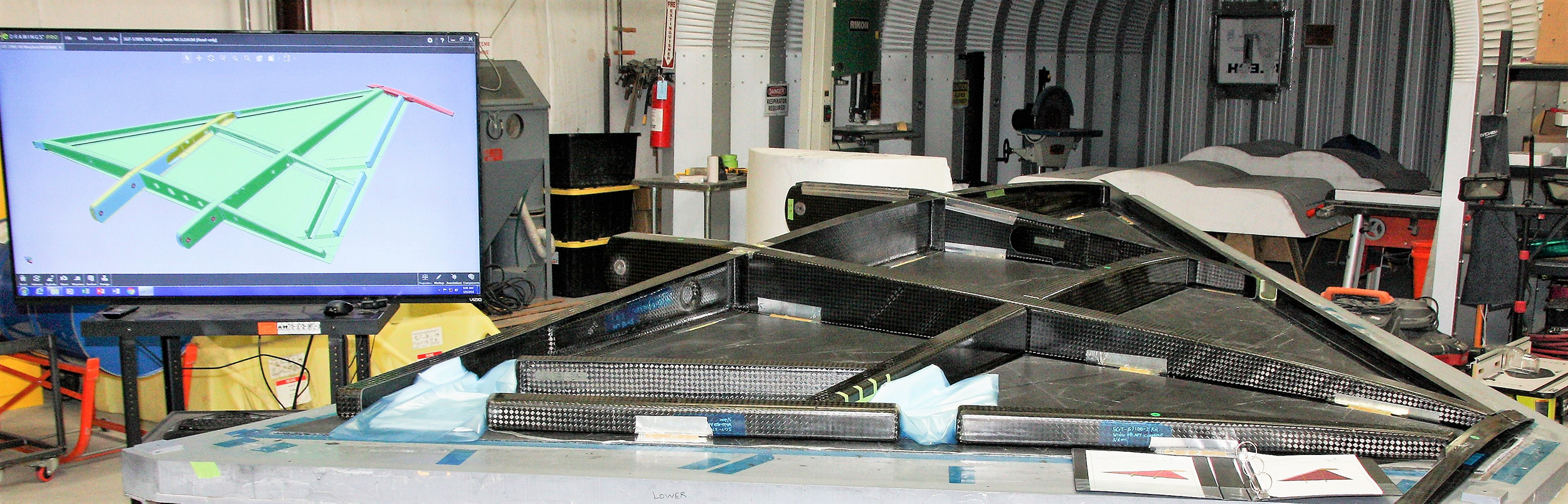

Sierra Technical Services’ Manufacturing Department produces high quality, durable, cost effective products that exceed industry standards.

STS manufactures components for a wide range of aerospace, to flat panels, to complex composite structures involving intricate layup schedules.

Our manufacturing services include:

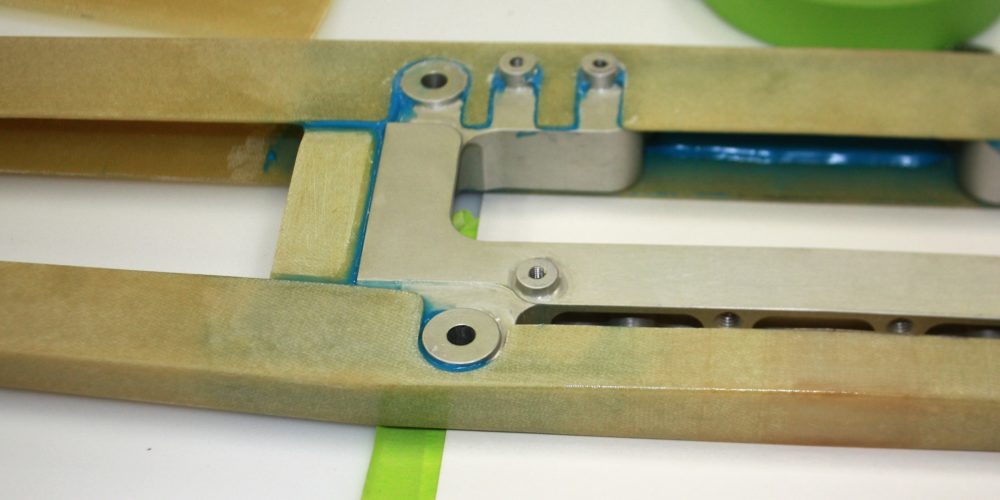

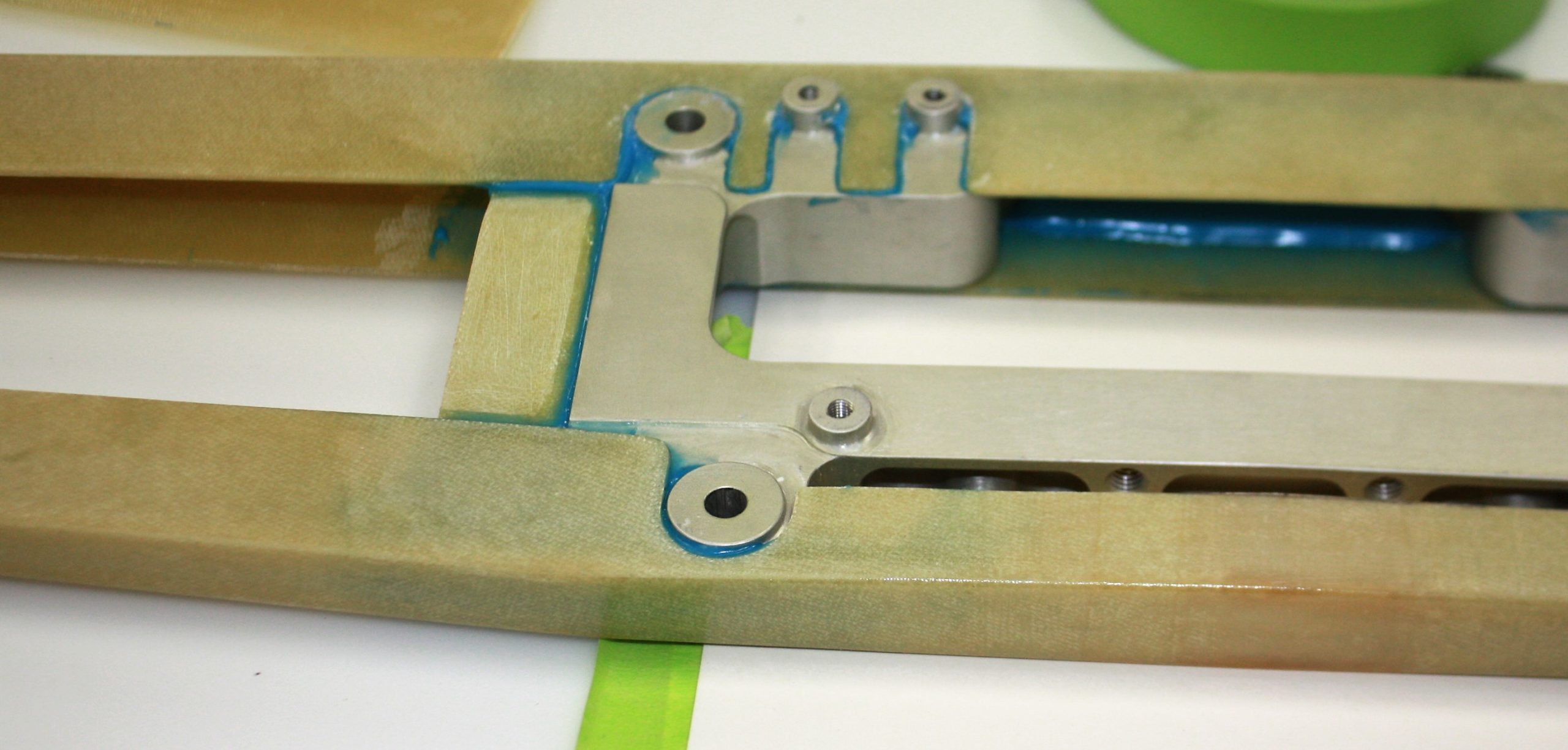

- Tooling Design & Manufacturing

- Composite Fabrication – Utilizing Out-of-Autoclave Processing Techniques

- Custom Metal Fabricating & Coating

- Airframe Assembly

- Aircraft Subsystems Installation & Integration

- Composite Repair

Our production methodology and configuration management system allows us to document the “As-Built” manufacturing process while maintaining stringent delivery timelines.

Our qualified composite technicians use Laser Projection Systems to digitally control ply & core placement of composite materials and parts, improving the speed and quality of critical aerospace components.